Virtuelle Inbetriebnahme

Die schnelle und einfache Lösung für Anlagen, die wirklich funktionieren.

HERAUSFORDERUNGEN

Virtuelle Inbetriebnahme für den innovativen Maschinenbau

NEXT LEVEL ENGINEERING. Facts konzentriert – jetzt alles erfahren

Von der virtuelle Inbetriebnahme zur Inbetriebnahme

Die zunehmende Verkürzung der Zeitfenster zwischen der ersten Anfrage und dem geforderten Abnahme- oder Liefertermin im Maschinen- und Anlagenbau erfordert einen effizienten Entwicklungsprozess, der bereits mit den ersten Kundengesprächen beginnt und frühzeitig verwertbare Ergebnisse liefert. In der agilen Softwareentwicklung steht mit der virtuellen Inbetriebnahme (VIBN) bzw. dem digitalen Zwilling ein leistungsfähiges Tool zur Verfügung, um diesen Herausforderungen zu begegnen.

Sparen Sie Zeit, Geld und minimieren Sie das Risiko von Fehlern in Ihren Entwicklungs- und Inbetriebnahmeprozessen. Steigern Sie die Qualität Ihrer Produkte mit einem modernen virtuellen Engineering – bleiben Sie wettbewerbsfähig.

Gestern – die klassische Inbetriebnahme

Durch die virtuelle Inbetriebnahme werden nicht nur Möglichkeiten zu technischen Verbesserungen an der Maschine, sondern zeitgleich an der Arbeitsweise aufgedeckt. Wenn dabei die Taktzeiten nicht optimal ausgelegt sind oder es im Produktionsprozess zu Kollisionen kommen könnte, kann dies präventiv vermieden werden. Auf diese Weise werden nur noch Maschinen und Anlagen montiert, die schon im Vorfeld getestet und optimiert wurden und so von vornherein ein hohes Maß an Leistung erbringen.

Hier geht es zum E-Paper

LÖSUNGEN – SO GELANGEN SIE AN IHR ZIEL

Ihr Fahrplan

Virtuelle Inbetriebnahme

Gestalten Sie Ihr Unternehmen zukunftsfähig mit der richtigen Simulation als Bindeglied aller Engineering-Bereiche.

Umgesetzt in wenigen Schritten

Erstellen Sie Ihr CAD Modell, egal ob u.a. in Creo, Inventor, IronCAD, Solid Edge oder SolidWorks.

Verbinden Sie reale Steuerungen (SPS und Roboter) mit dem Modell.

Überprüfen Sie das Zusammenspiel von Mechanik und Software direkt am Bildschirm.

Wo drohen Kollisionen? Profitieren Sie von der bidirektionalen CAD-Schnittstelle und beheben Sie Fehler im Handumdrehen.

Spielen Sie unterschiedliche Szenarien durch und finden die optimale Variante. Einfach und schnell.

Fertig ist der digitale Zwilling!

Setzen Sie den digitalen Zwilling parallel zur Produktion ein und überwachen so die Anlage im laufenden Betrieb.

Hier nachlesen, wie es andere machen

VORTEILE

Viele Vorteile, aber auch Grenzen

Verbessertes Engineering

Virtuelle Inbetriebnahme – Vorteile und Grenzen

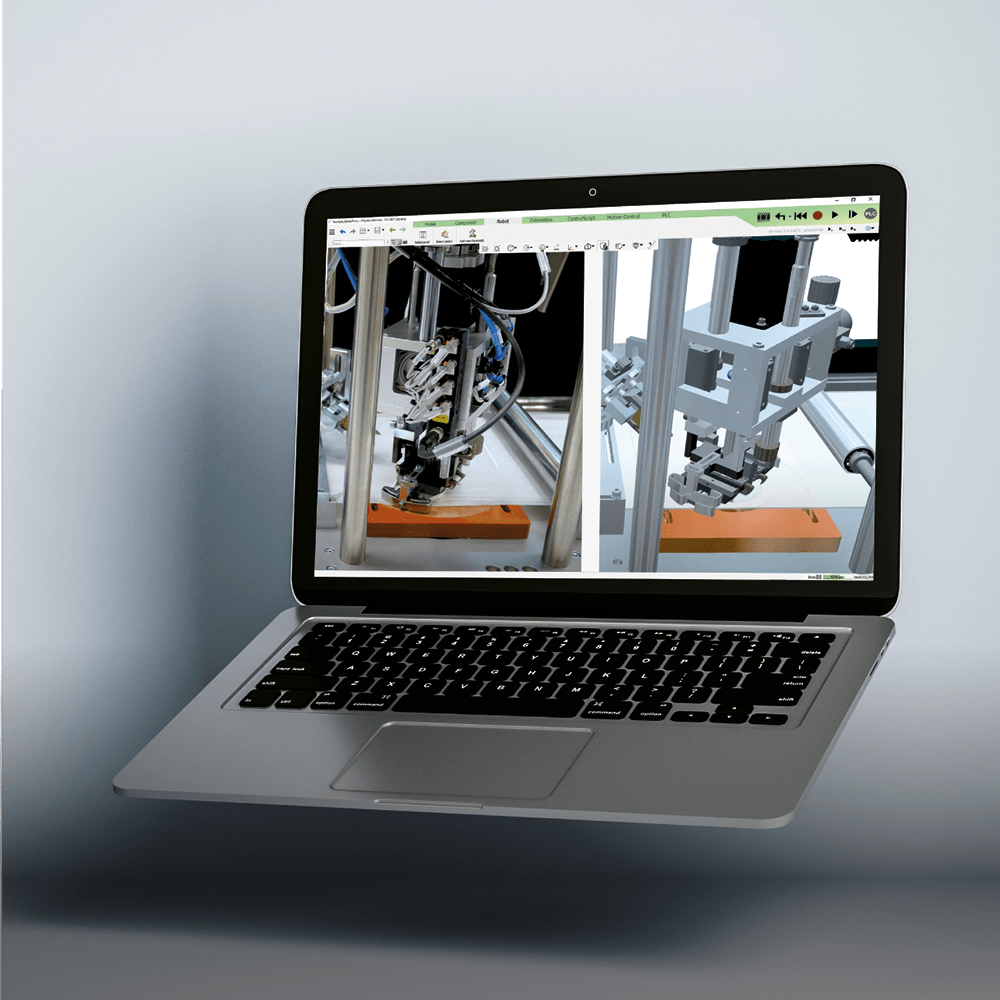

Besonders das Engineering profitiert von der virtuellen Inbetriebnahme und von dem digitalen Zwilling, da so schon in der Konstruktionsphase die spezifischen Vorgaben des Kunden umgesetzt und gleichzeitig auf Machbarkeit überprüft und Lösungen vorab getestet werden können. Das Risiko von fehlerhaften Planungen wird hierdurch effektiv vermindert und gleichzeitig die Qualität der Software, der Anlagen und der Maschinen verbessert. Zugleich erleichtert die VIBN ebenfalls die Einbindung der Anlage bzw. der Maschine in die bestehende reale Umgebung im laufenden Betrieb.

Die virtuelle Inbetriebnahme stützt sich auf ein Simulationsmodell, das in der Lage ist, das Verhalten äußerst genau nachzubilden.

Ihre wichtigsten Vorteile auf einen Blick

Kürzere Projektlaufzeit

Natürlich kann dabei nicht auf den Ingenieur verzichtet werden. Doch der Einsatz einer virtuellen Inbetriebnahme ermöglicht es, die Reisetätigkeit zu den Kunden deutlich zu reduzieren. In einem globalhandelnden

Natürlich kann dabei nicht auf den Ingenieur verzichtet werden. Doch der Einsatz einer virtuellen Inbetriebnahme ermöglicht es, die Reisetätigkeit zu den Kunden deutlich zu reduzieren. In einem globalhandelnden Arbeitsgebiet wie dem Anlagen- und dem Maschinenbau ist das ein großer Vorteil. So nimmt die eigentliche Inbetriebnahme etwa ein Viertel der gesamten Projektlaufzeit in Anspruch. Wenn die Anlage oder die Maschine in ein bereits bestehendes System integriert wird, reduzieren sich durch eine VIBN zudem die Ausfallzeiten der Maschinen und der Anlagen bei der Systemumstellung. Diesen Vorteil können Anlagen- und die Maschinenbauer schon bei den Verhandlungen für sich nutzen. Vor allem kleine und mittlere Unternehmen gewinnen durch die VIBN eine größere Flexibilität und können sich so gegenüber Großunternehmen positionieren.

Einfaches Retrofitting

Zu den großen Vorteilen einer virtuellen Inbetriebnahme gehört vor allem, dass sie sich ebenfalls auf das Retrofit und die Umkonfiguration von Anlagen und Maschinen

Zu den großen Vorteilen einer virtuellen Inbetriebnahme gehört vor allem, dass sie sich ebenfalls auf das Retrofit und die Umkonfiguration von Anlagen und Maschinen anwenden lässt. Die Voraussetzung dafür ist der digitale Zwilling, das virtuelle Pendant zur realen Maschine, in welchem nicht nur der derzeitige Zustand, sondern auch zwischenzeitlich durchgeführte Änderungen festgehalten sind, wie zum Beispiel der Ersatz eines beschädigten Sensors durch ein anderes Produkt und die hiermit verbundene Adaption der Steuerungssoftware.

Schnellere Fertigstellung

Auch die Inbetriebnahmezeiten können durch die virtuelle Inbetriebnahme signifikant verringert werden. Dieser Umstand ist besonders im Anlagenbau und verbunden

Auch die Inbetriebnahmezeiten können durch die virtuelle Inbetriebnahme signifikant verringert werden. Dieser Umstand ist besonders im Anlagenbau und verbunden mit der 3D- Simulation und Simulationssoftware einer der größten Hebel, um die Entwicklungs- und Produktionskosten so gering wie möglich zu halten. In den einzelnen Entwicklungsphasen können so häufige Mehraufwendungen auf ein Minimum reduziert werden.

Frühzeitige Fehlerbehebung

Welche weiteren Vorteile hat eine VIBN? Das Engineering profitiert vor allem von der virtuellen Inbetriebnahme, da schon in der Konstruktionsphase die spezifischen

Welche weiteren Vorteile hat eine VIBN? Das Engineering profitiert vor allem von der virtuellen Inbetriebnahme, da schon in der Konstruktionsphase die spezifischen Anforderungen des Kunden prüfbar sind. Besonders komplexe Zusammenhänge zwischen den einzelnen Maschinen- und Anlagenbereichen werden daher schon im frühen Engineering beachtet und Lösungen vorab getestet. Das Risiko möglicher Fehlplanungen wird hierdurch effektiv vermindert, die Qualität der Anlagen und der Maschinen optimiert. Ebenso erleichtert die VIBN vor allem die Einbindung der Maschine in die reale Produktionsumgebung in der Produktion, was ein erheblicher Vorteil ist.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Unser Trendpaper mit allen Vorteilen der VIBN herunterladen

PRAXIS-TIPPS

Themen rund um die virtuelle Inbetriebnahme

Wissen wie es funktioniert

PRODUKTE

Das ganze Spektrum aus einer Hand

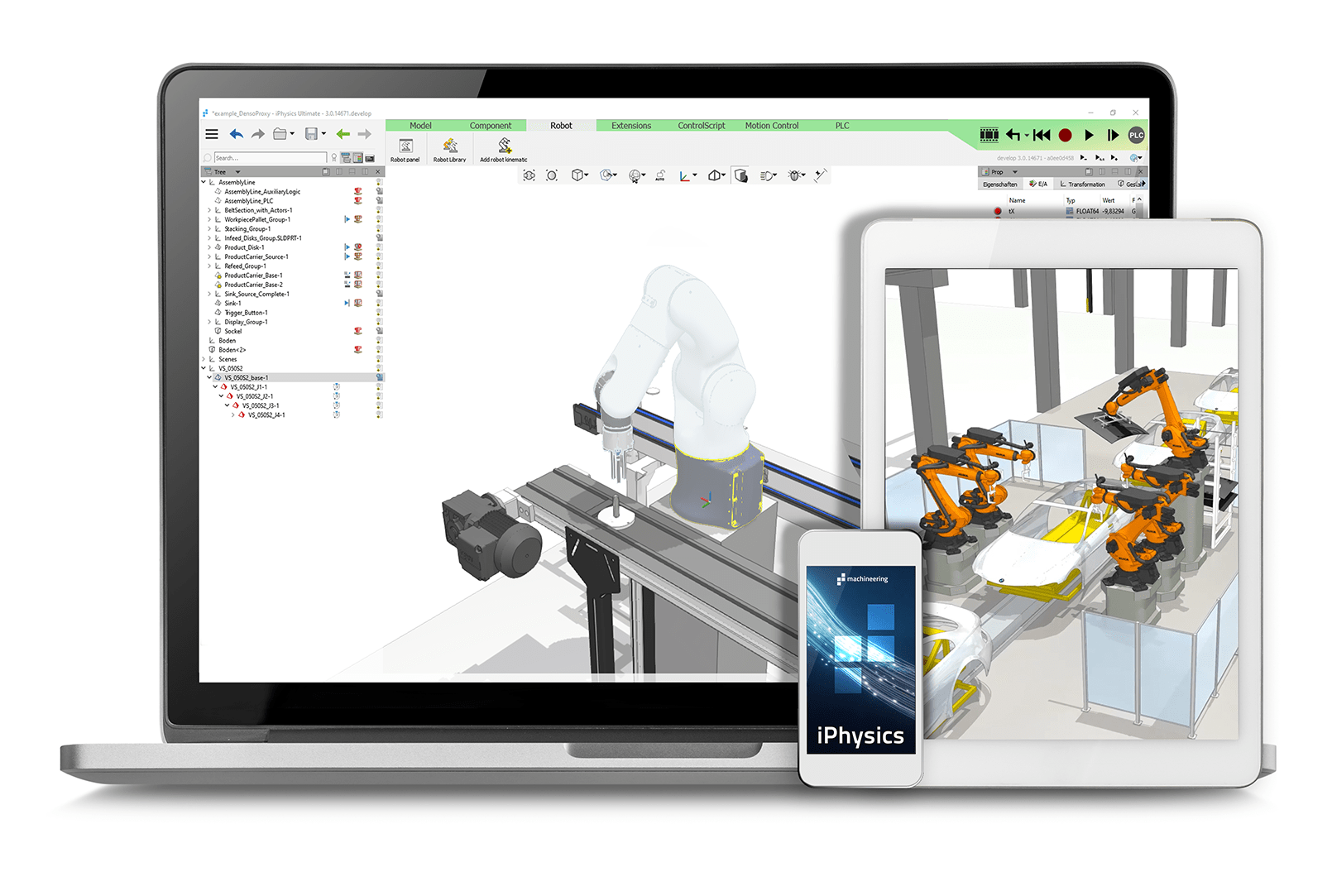

machineering entwickelt die innovative Simulationslösung iPhysics für die Echtzeit-Materialfluss- und Robotersimulation. Wir sind ein Team aus der Praxis: Experten aus unterschiedlichen fachlichen Disziplinen beraten branchenübergreifend seit mehr als 15 Jahren Unternehmen zu allen Themen rund um die Simulation, Fabrikplanung, virtuelle Inbetriebnahme, industrial Metaverse, IIOT und KI.

Das ganze Spektrum aus einer Hand

Sie wollen eine virtuelle Inbetriebnahme in Ihren Prozess intergrieren? Fehler schon frühzeitig erkennen und vermeiden? Die Maschinen in Echtzeit überwachen?

iPhysics

Sie wünschen sich die perfekte Ergänzung für Ihre Simulationssoftware? Der Digital Twin oder die HoloLens sollen Teil Ihrer Simulationsumgebung werden?

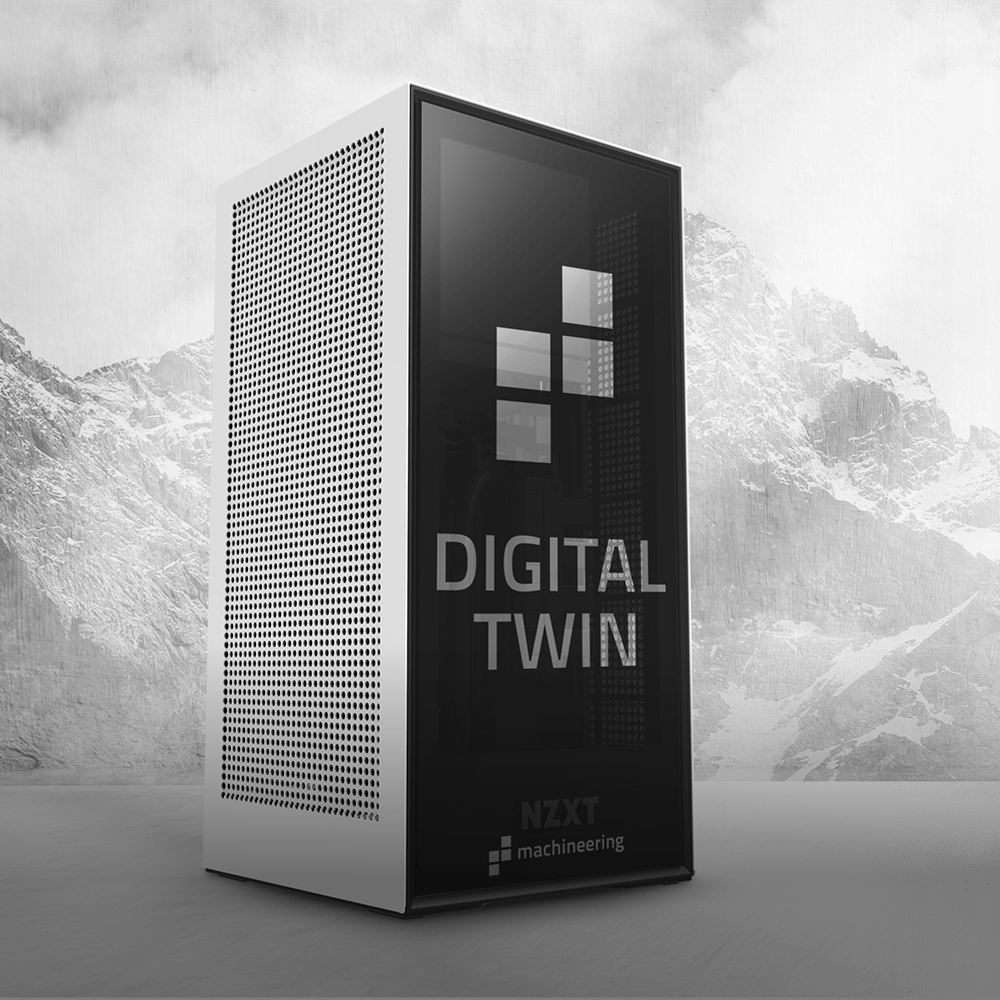

Hardware

Wir machen Ihre Modelle messefein. Oder Sie brauchen Unterstützung bei der Durchführung der virtuellen Inbetriebnahme? Wir sind für Sie da!

Services

iPhysics für herausragende, performante Simulation.

Ultimate, Showroom und Runtime.

Highend Technik in höchster Qualität made in Germany.

Digital Twin Box, FieldBox, iPhysics App.

iPhysics für herausragende, performante Simulation.

Ultimate, Showroom und Runtime.

iPhysics

Hardware

Services

Highend Technik in höchster Qualität made in Germany.

Digital Twin Box, FieldBox, iPhysics App.

Rundum betreut. Von Anfang an. Ihr Auftritt ist unsere Passion.

Beratung, Unterstützung, Ausarbeitung.

BEST PRACTICE

iPhysics im Einsatz

Unsere Kunden haben iPhysics bereits erfolgreich in ihren Unternehmen integriert und dabei beeindruckende Ergebnisse erzielt. Von der Optimierung ihrer Produktionsprozesse bis zur Reduzierung von Ausfallzeiten und der Förderung innovativer Produktentwicklungen hat iPhysics eine Vielzahl von Herausforderungen gemeistert. Die Erfahrungen unserer Kunden zeigen, wie iPhysics die Unternehmen dabei unterstützen kann, ihre Ziele zu erreichen und weiter zu wachsen.

Hier gibt es die ganzen Geschichten

WEBINARE

Unsere kostenfreien Webinare und Workshops

Noch unsicher? Lernen Sie iPhysics kennen

Stellen Sie Ihre Fragen und nutzen Sie unsere kostenlosen Webinare zur Einführung in das Thema virtuelle Inbetriebnahme. Testen Sie auch unsere unverbindlichen Schnupperkurse, um eine Einführung in die Software zu erhalten und zu erfahren, wie Sie diese am besten in Ihrem Unternehmen einsetzen können.

Von der virtuellen Inbetriebnahme zum digitalen Zwilling

Das virtuelle Pendant entsteht

Virtuelle Inbetriebnahme – eine Investition, die sich rechnet

Zeit und Geld sparen mit iPhysics

Jetzt ePaper zu iPhysics downloaden

Lohnt sich das für mich?

Sie wollen wissen, ob auch Ihr Unternehmen von der virtuellen Inbetriebnahme profitiert? Oder ob der digitale Zwilling für Sie Sinn macht?

Jetzt den kostenfreien Check machen

IHR ANSPRECHPARTNER

Auf ein Gespräch

Als Maschinenbauer kenne ich die Herausforderungen unserer Branche aus erster Hand. Mit der Gründung von machineering habe ich es mir zur Aufgabe gemacht, diese Probleme bereits im Vorfeld der realen Inbetriebnahme weitestgehend zu lösen. Die Entwicklung von iPhysics ist das Ergebnis dieser Leidenschaft und Expertise. Ich bin mit Herzblut dabei – denn iPhysics wurde von Maschinenbauer für Maschinenbauer entwickelt

Buchen Sie eine kostenlose Beratung mit mir oder meinem Team