Artificial Intelligence in Mechanical Engineering

What is artificial intelligence (AI) in the context of mechanical engineering?

Artificial intelligence in mechanical engineering refers to the integration of computer technologies and algorithms that have been developed to introduce human-like intelligence and learning capabilities into machines and production processes. Essentially, it is about designing machines and systems that can perform tasks that normally require human thought and action. This includes machine learning, neural networks, machine vision and other technologies that allow machines to analyze data, recognize patterns, make decisions and continuously improve.

AI can be applied to mechanical engineering in different areas, from product development to production optimization and quality control. Integrating AI offers numerous benefits, including improved efficiency, quality and sustainability in manufacturing.

The combination of sensory data, advanced algorithms and powerful hardware makes it possible to make machines and plants smarter and more autonomous. At a time when the Fourth Industrial Revolution (Industry 4.0) and digitization are becoming more and more important, AI has become a decisive factor in how competitive companies truly are in mechanical engineering.

However, AI in mechanical engineering goes beyond automation; large amounts of production data can be analyzed in real time, and predictive maintenance can be performed to minimize unplanned downtime. It can also help manufacture customized products more efficiently and cost-effectively, as AI systems can optimize their design and production.

Overall, AI in mechanical engineering represents a significant technological development that is pushing the industry towards greater efficiency, precision and sustainability. Nevertheless, it is important to keep in mind challenges in terms of data protection, shortages of skills and ethical responsibility, in order to fully tap the potential of AI in this sector.

Start process optimization in your company today. Our experts will be happy to advise you on how to make the best use of iPhysics to achieve optimal results.

Simulation and prototyping with AI

Using AI in mechanical engineering also extends to the exciting topic of simulation and prototyping – a crucial part of creating new products and machines. With the help of AI, engineers and designers can create realistic virtual models during virtual commissioning that can predict how products will behave in different scenarios. This results in more efficient product development, as it is possible to detect and correct any design errors early.

AI-based simulations can accurately imitate complex physical processes and provide a realistic basis for prototype design. This not only saves time and resources, but also makes it possible to turn innovative ideas into reality more quickly. Plus, AI in prototyping can help companies choose the best design from a range of options, based on both previous simulation results and specific requirements.

Learn more about iPhysics and its benefits for your company. Test it for free and without obligation with our live demo.

Using AI to improve manufacturing processes

Integrating AI into manufacturing processes is a decisive step towards greater efficiency and quality in mechanical engineering. AI systems can analyze large amounts of production data in real time and deliver valuable information. They are able to monitor production processes, identify bottlenecks, and automatically make adjustments to eliminate such bottlenecks and optimize production.

AI can also be used to predict production downtime and quality problems by detecting anomalies in data before they lead to serious issues. This means proactive measures can be taken and downtime minimized. In addition, AI can assist with resource allocation by optimizing energy consumption and material usage.

Integrating AI into manufacturing offers incredible cost-saving potential and an increase in competitiveness. Mechanical engineering companies that successfully use this technology can develop more flexible and efficient processes that meet the market’s ever-increasing demands.

Learn more – our user reports give insight into how other companies have successfully put iPhysics to use.

AI in factory planning

AI can be used in various ways to improve processes and increase efficiency in factory planning. Here are just a few examples:

- Process optimization: AI can be used to develop complex algorithms that optimize machines and processes in mechanical engineering. For example, AI models can be used to monitor and control production processes to achieve greater efficiency and quality.

- Optimizing production processes: AI can be used to optimize production processes. Using algorithms and machine learning to recognize complex data patterns in order to identify bottlenecks and improve processes.

- Quality control: AI can be used to develop automated systems for quality control. Image recognition algorithms, for instance, can detect defects or production deviations and monitor quality.

Predictive maintenance: By using sensor data and machine learning, AI can help monitor the condition of machinery and equipment in real time. This helps predict potential failures which ultimately leads to plannable maintenance and a reduction in downtime.

Inventory management: AI can also help optimize inventory management. By analyzing historical data and external factors such as delivery times or customer demand, AI can assist in inventory planning and forecasting.

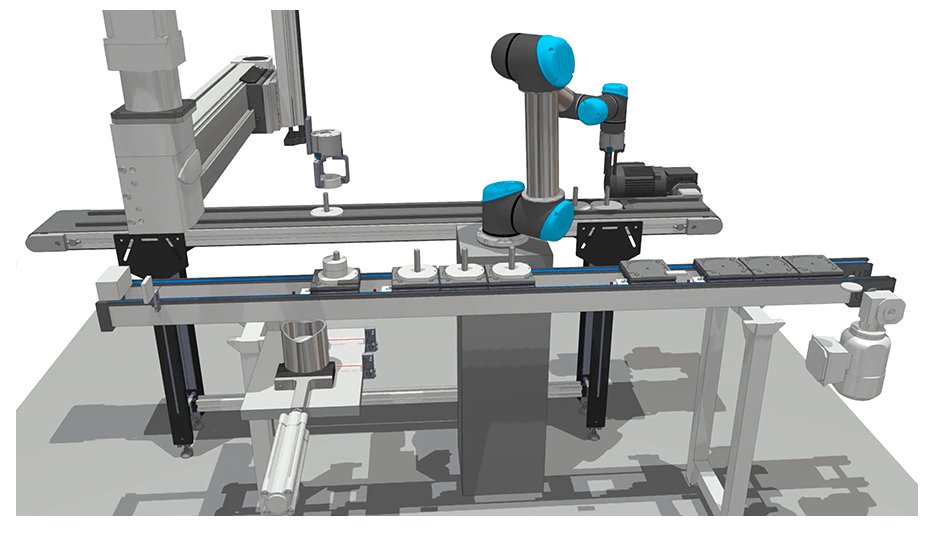

Robotics and automation: AI-controlled robots and automated systems are becoming increasingly important in factory planning. AI can help equip robots with advanced sensors and control systems to automate tasks such as assembly, packaging or handling of materials.

Make the upgrade. Let us assist you in your planning. Learn more in our free webinar.

Automated inspection and error detection with AI systems

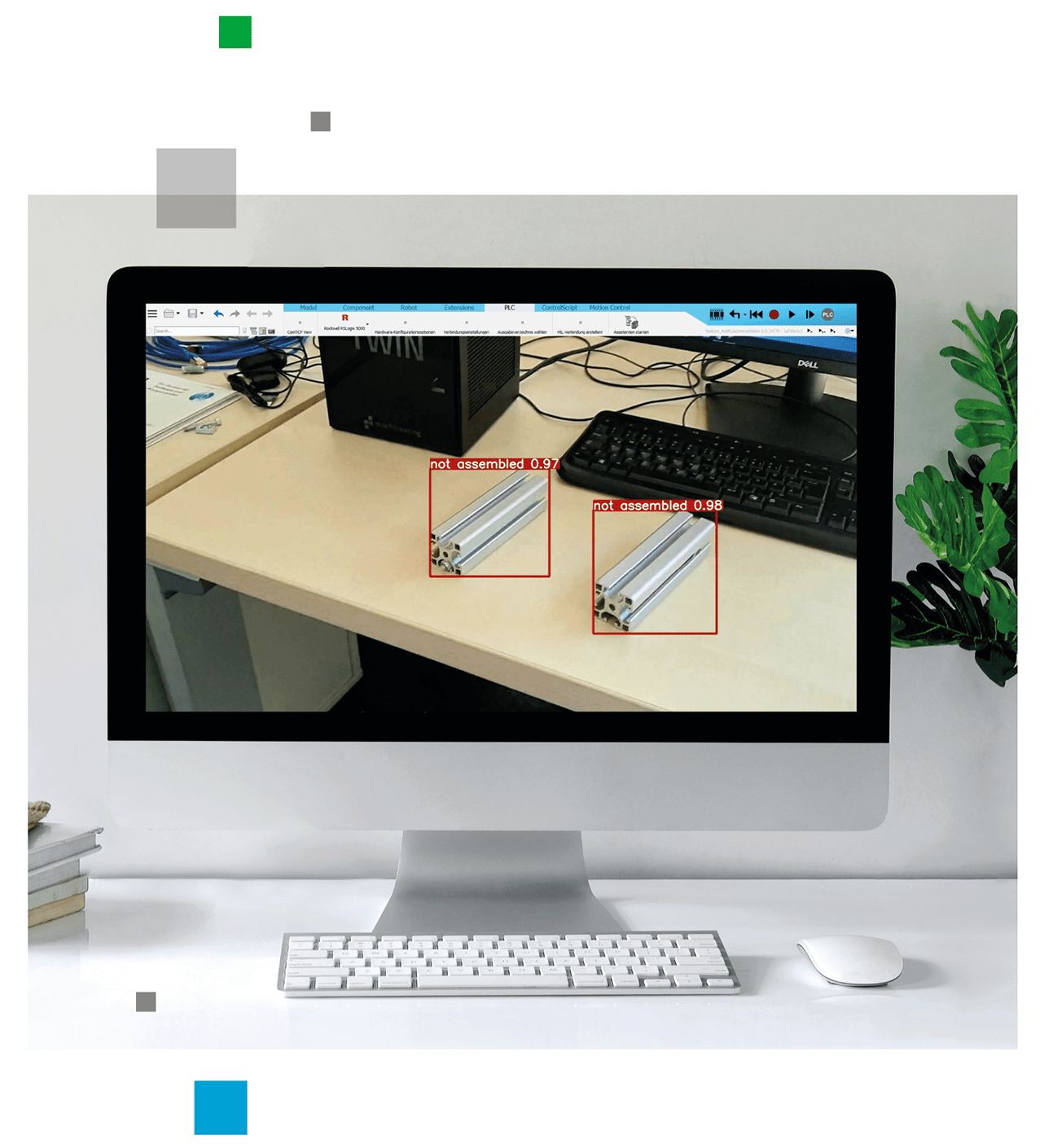

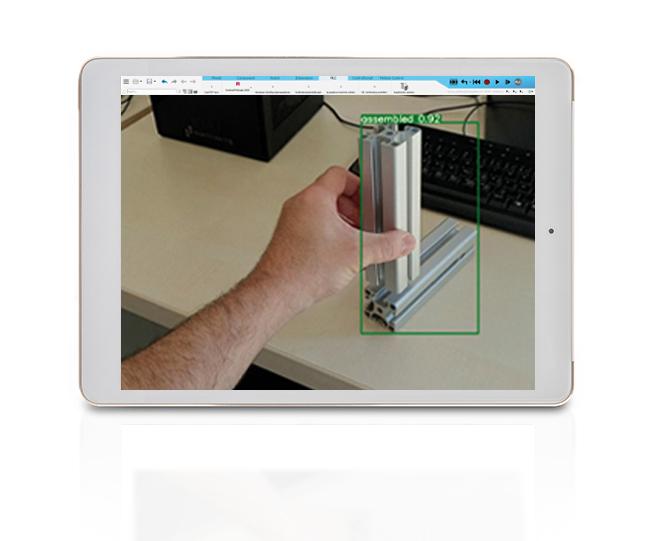

Quality control in mechanical engineering sees significant benefits from artificial intelligence. AI systems are able to automate inspection processes and precisely detect defects. This is often done with the help of image processing technologies and machine learning.

By using AI, products can be inspected for defects and irregularities during the manufacturing process or after their completion. AI systems can detect small defects that are difficult for the human eye to see. This leads to a significant improvement in the quality of products, as well as fewer rejects.

Automating quality control through AI not only saves time, it also enables consistent quality to be maintained during production. In addition, AI systems can collect historical data and identify trends in quality, which helps improve manufacturing processes.

Get the most from your company. Optimize your processes with our simulation software, iPhysics, and reap all the benefits.

Talk to us to determine your savings potential.

Based on the synthetic data in iPhysics, the AI identifies good parts.

Improvements in product quality and reduction of waste

Artificial intelligence plays a crucial role in quality control, improving product quality and reducing waste. AI systems allow for more precise monitoring of production processes, allowing companies to detect quality problems early.

By using AI, mechanical engineering companies can identify defective products in real time and reduce the number of rejects. This leads to significant cost savings and an increase in the overall quality of the goods produced. Additionally, AI can help reduce human error in quality control and ensure consistency in the quality of products.

Continuous monitoring and improvement of product quality with AI not only leads to more satisfied customers, but also to a more competitive edge. Companies that integrate AI into their quality control processes can produce high-quality products more efficiently while minimizing waste and the need for rework. This not only leads to lower costs, but also increased customer satisfaction and confidence in the dependability of products.

Using AI to improve product quality and reduce waste is a crucial step for engineering companies to succeed in a competitive market. It enables greater efficiency, higher-quality products and increased customer satisfaction, which in turn contributes to a company’s long-term success.

Get the most from your company. Optimize your processes with our simulation software, iPhysics, and reap all the benefits.

Talk to us to determine your savings potential.