Industrial Metaverse – the Virtual World of Industry

What is the industrial metaverse?

The metaverse is a term used to describe a virtual, 3D world that users can visit and experience. It is a type of virtual world made possible by digital technologies such as virtual reality (VR), augmented reality (AR) and artificial intelligence (AI).

While the metaverse is still in its early stages of development, there are already technologies that make it possible to experience and apply it. However, the metaverse is expected to grow and evolve over the next few years, especially with the emergence of new technologies such as 5G, cloud computing and AI.

Even today, the metaverse is beginning to influence many areas of life, from the way we work and learn to the way we spend our freetime and communicate with each other. It is an exciting new world that offers many opportunities while raising some challenges and concerns, including privacy, security and social impact

Learn more about AI and what this new technology can do for your company.

What role does the industrial metaverse play in mechanical engineering?

The metaverse already plays a crucial role in the design, development and production of machines and systems.

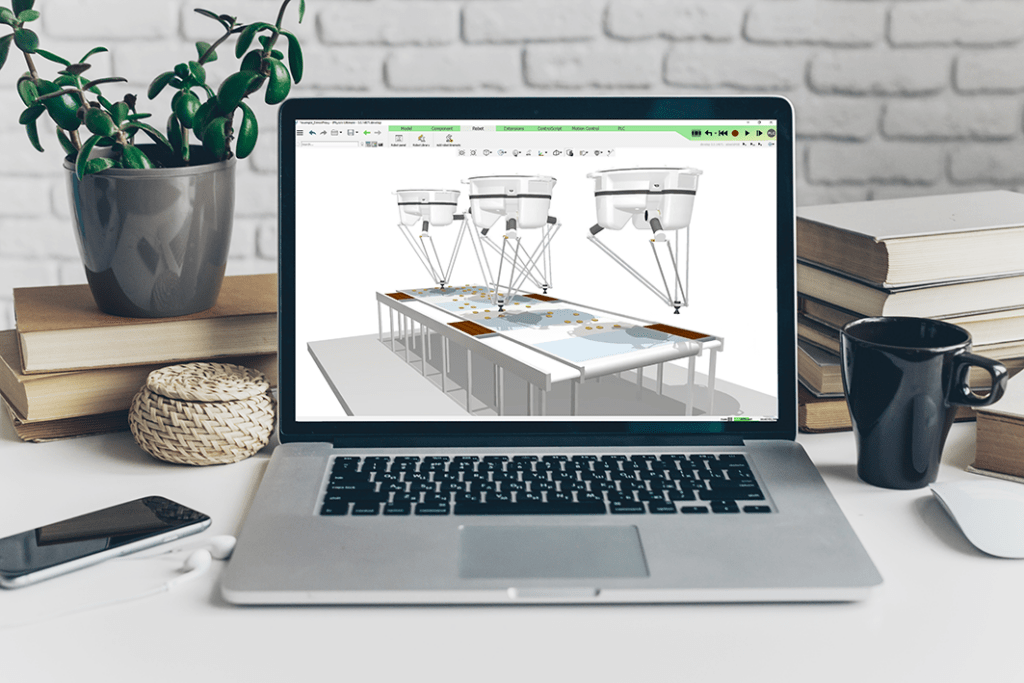

Simulation software such as iPhysics opens up a whole new dimension of the metaverse to users.

In which areas of mechanical engineering can the metaverse be used?

- Conception and development of machines and products

Engineers create virtual prototypes and models that can be tested and improved with virtual commissioning. This ultimately leads to faster and more effective development processes, as changes to the virtual models can be made more quickly, with less time needed and lower cost compared with physical prototypes.

- Employee training

Companies can offer virtual training and workshops for employees to learn the skills and knowledge they need for their work. This could be especially useful for employees working remotely and teams situated across different locations.

- Manufacturing of machines and products

Companies can simulate virtual factories and manufacturing processes to improve efficiency and productivity. This helps reduce the number of physical prototypes and test runs needed, resulting in cost savings and faster rollout of new products.

Learn more about iPhysics and its benefits for your company. Test it for free and without obligation with our live demo.

What role does the industrial metaverse play in factory planning?

The metaverse offers many advantages not only in the development of new machines, but also in the planning of entire factories. Virtual factories can be created to simulate and optimize the flow of materials, production environments and individual workstations.

Learn more – our user reports give insight into how other companies have successfully put iPhysics to use.

How can the industrial metaverse be used in factory planning?

- Virtual production lines

In the metaverse, virtual production lines can be created to simulate assembly processes and production. This means companies can optimize operations before they are put to use in the real world, and they can identify and fix errors and bottlenecks before they occur.

- Real-time monitoring and controlling

Factories can be monitored and controlled in real-time in the metaverse. This allows companies to react quickly to changes and make production more efficient.

- Training

The metaverse offers effective possibilities to train employees in new production processes and technologies by offering virtual training opportunities.

- Cost efficiency

Using the metaverse in factory planning can lead to significant cost savings, as companies have the opportunity to optimize design and production processes in the virtual world before they are rolled out in the real world.

- Collaboration and communication

The metaverse gives companies an effective way to improve collaboration and communication between teams and departments. The metaverse can provide virtual spaces and workspaces where employees can work together, regardless of where they actually are.

Make the upgrade. Let us assist you in your planning. Learn more in our free webinar.

What role does the industrial metaverse play in the implementation of the Fourth Industrial Revolution (Industry 4.0) principles?

The Fourth Industrial Revolution, or Industry 4.0, involves the networking and automation of manufacturing processes using advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI) and big data analytics.

How can the metaverse support the Fourth Industrial Revolution?

- Virtual factory planning:

Using the metaverse, companies can plan virtual factories where they simulate and optimize manufacturing processes before they are put to use in the real world. This helps reduce errors and downtime while improving productivity and efficiency.

- Virtual training:

The metaverse can be used to train employees in new technologies and production processes. It offers an attractive and immersive environment where staff can improve their skills and gain more knowledge.

- Remotely monitor industrial facilities and equipment:

The metaverse gives companies the opportunity to remotely monitor and service equipment to increase efficiency and flexibility in production. Sensors and cameras can be used to collect real-time data and display it in the virtual environment.

- Collaborative development:

The metaverse offers a collaborative environment in which teams and departments can work on projects together. The interactive nature of the virtual world can improve collaboration and encourage innovation.

- Efficiency and quality:

By automating, optimizing and monitoring production processes, the metaverse can contribute to improvements in the efficiency and quality of production.

Make the switch today. With our training courses, we help your employees get ready for the metaverse – and the future.