Virtual commissioning and digital twins for innovative mechanical engineering.

The fast and easy solution for systems that really work.

Challenges

Virtual commissioning for innovative mechanical engineering

NEXT-LEVEL ENGINEERING. Facts & figures – learn more now

From virtual commissioning to actual commissioning

The increasing shortening of the time window between the first inquiry and the required acceptance or delivery date in mechanical and plant engineering requires an efficient development process that begins with the first customer meetings and delivers usable results at an early stage. In agile software development, virtual commissioning (VIBN) or the digital twin is a powerful tool for meeting these challenges.

Save time, money and minimize the risk of errors in your development and commissioning processes. Increase the quality of your products with modern virtual engineering – stay competitive.

Yesterday – the classic commissioning

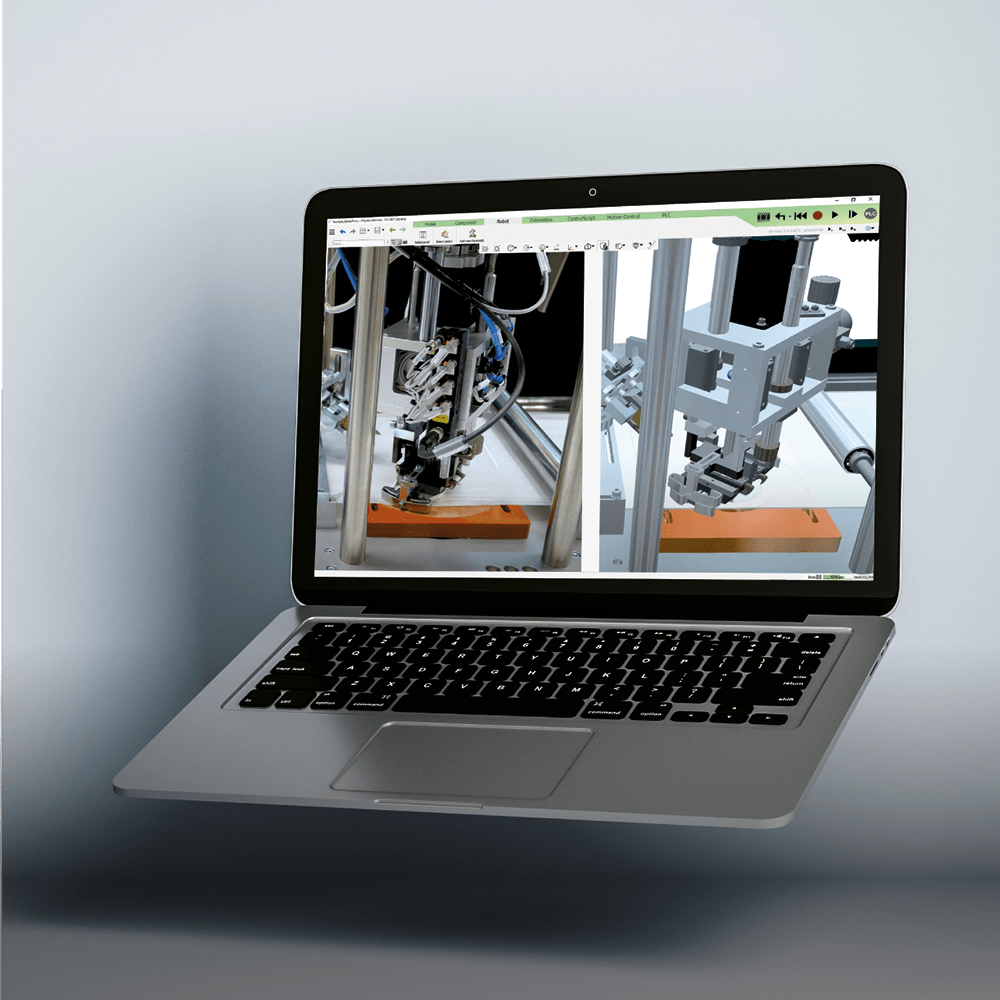

Virtual commissioning is the early testing of planned machines and systems with simulation software, the virtual system. This is later used to create a digital twin with real commissioning. Depending on the appearance of the simulation tool, static or dynamic commissioning is carried out. Programs optimized with the help of the mechatronic model can then be safely transferred to the real system or to the machine, plant or robot. With virtual commissioning, errors can be identified early on and thus be easily avoided in early development phases. This helps avoid costly and time-consuming improvements to the actual system.

Click here for the e-paper

SOLUTIONS - how to reach your goal

Your Road map

Virtual commissioning

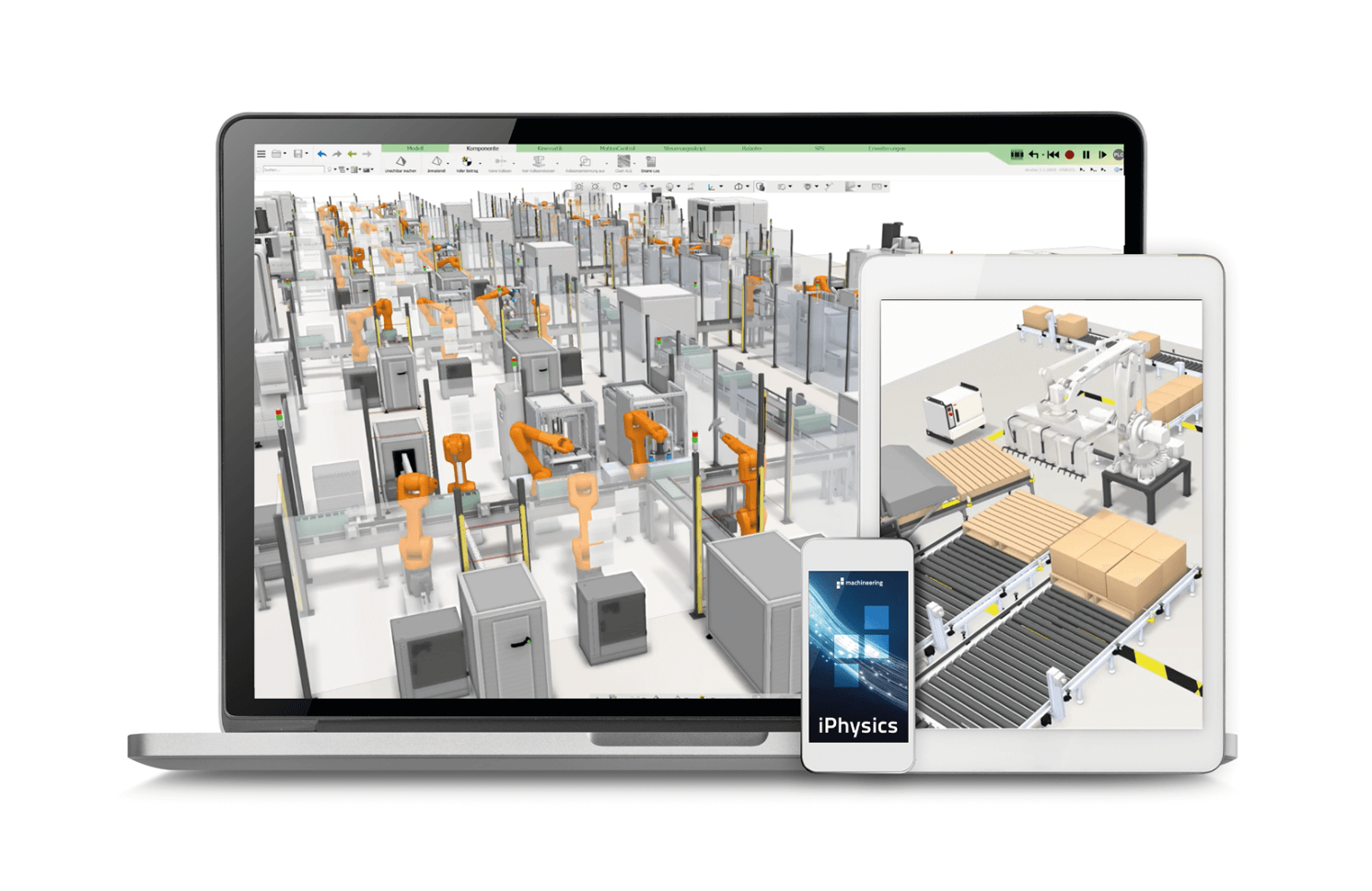

Get your company ready for the future – the right simulation links all areas of engineering.

Implemented in just a few steps

Create your CAD model, no matter whether you use Creo, Inventor, IronCAD, Solid Edge or SolidWorks.

Transfer the CAD model to iPhysics at the touch of a button and create a simulation model.

Connect real controllers (PLC and robots) to the model.

See how mechanics and software interact directly on your screen.

Where could collisions occur? Benefit from the two-way CAD interface and fix errors in no time at all.

Run through different scenarios and find the ideal version.

Quick and easy!

Use your digital twin at the same time as production and monitor the system in operation.

Use the digital twin for predictive and remote maintenance to keep machine downtime as short as possible.

Impress your customers. Use your digital twin for sales, at trade fairs with AR or VR, or for training.

Read here how others do it

ADVANTAGES

Many advantages – but also limitations

Improved engineering

Virtual commissioning – benefits and limitations

Virtual commissioning and the digital twin especially benefit engineering, since specific customer requirements can be included and tested for feasibility as early as the design phase. Particularly complex connections between the different areas of the machines and systems can be taken into account in early engineering phases, and solutions can be tested in advance. This effectively reduces the risk of possible planning errors and optimizes the quality of the systems and machines. At the same time, virtual commissioning also makes it easier to integrate the machine or system into the real production environment while it is in operation.

Your most important benefits at a glance

Shorter project timelines

It goes without saying that engineers are still crucial. But virtual commissioning benefits companies by significantly reducing the amount spent travelling to customers. This is a huge advantage in a global field like systems and mechanical engineering. Actual commissioning often takes up about a quarter of the entire project time.

In cases when the system or the machine is to be integrated into an existing system, the benefits of virtual commissioning also include reduced downtimes during system changeover – something plant and mechanical engineers can use to their advantage during negotiations. Small and medium-sized companies in particular gain greater flexibility through virtual commissioning and are thus able to better position themselves to compete with large companies.

Easy retrofitting

One of the major benefits of virtual commissioning is that it can also be used for retrofitting and reconfiguring machines and systems.

This requires a digital twin, the virtual counterpart to a real machine. The digital twin not only contains the current status, but also records any changes made, such as the replacement of a damaged sensor and the associated changes to the control software.

Faster completion

The time needed for commissioning can also be significantly reduced with virtual commissioning.

When combined with 3D simulation and simulation software, this is a decisive factor for keeping development and production costs as low as possible in plant construction. In the individual development phases, common additional expenses can be reduced to a minimum.

Early error detection

What are the other benefits of virtual commissioning? Virtual commissioning especially benefits engineering, since specific customer requirements can be tested as early as the design phase.

Particularly complex connections between the different areas of the machines and systems can be taken into account in early engineering phases, and solutions can be tested in advance. This effectively reduces the risk of possible planning errors and optimizes the quality of the systems and machines. Virtual commissioning also makes it easier to integrate the machine into the real production environment, providing users with a significant advantage.

HAND-ON TIPS

Topics relating to virtual commissioning

Know how it works

PRODUCTS

Our products for virtual engineering

Our customers have already successfully integrated iPhysics into their companies and achieved impressive results. From optimizing their production processes to reducing downtime and driving innovative product development, iPhysics has overcome a variety of challenges. Our customers’ experiences show how iPhysics can help companies achieve their goals and continue to grow.

All from a single source

All from a single source

Do you want to integrate virtual commissioning into your process? To detect and avoid errors at an early stage? To monitor machines in real-time?

iPhysics

Would you like the perfect complement to your simulation software? Should a digital twin or HoloLens become a part of your simulation environment?

Hardware

We get your models ready for the trade fair. Or perhaps you need support in carrying out virtual commissioning? We’re here for you!

Services

iPhysics for excellent, high-performance simulation.

Ultimate, Showroom and Runtime.

High-end technology of the highest quality – made in Germany.

Digital Twin Box, FieldBox, iPhysics App.

BEST PRACTICE

iPhysics in use

Our customers have already successfully integrated iPhysics into their companies and achieved impressive results. From optimizing their production processes to reducing downtime and driving innovative product development, iPhysics has overcome a variety of challenges. Our customers’ experiences show how iPhysics can help companies achieve their goals and continue to grow.

Here are all the stories

WEBINARS

Our free webinars and workshops

Still unsure? Get to know iPhysics

Ask your questions and take advantage of our free webinars for an introduction to virtual commissioning. You can also try out our no-obligation taster courses to get an introduction to the software and find out how you can best use it in your company.

Free trial

Download iPhysics ePaper now

Is this valuable for me?

Would you like to know if your company could benefit from virtual commissioning? Want to find out if a digital twin is right for you?

Check for free now

YOUR CONTACT

To a conversation

As a mechanical engineer, I know the challenges of our industry at first hand. With the founding of machineering, I have made it my mission to solve these problems as far as possible in the run-up to real commissioning. The development of iPhysics is the result of this passion and expertise. I put my heart and soul into it – because iPhysics was developed by machine builders for machine builders

Book a free consultation with me or my team