Simulation Software for Real Virtual Engineering

What is simulation software?

Simulation software is a tool that makes it possible to virtually simulate and analyze a specific system or process. Different parameters and input are simulated to make predictions about how a system of a machine or plant will act.

In industry, this software is often used for product planning and, with a digital twin, it can be used to monitor running machines. In product planning, engineers can create a virtual model to test the behavior of a planned plant or machine with different components under different conditions, all before it is actually built. For example, you can simulate the behavior of a machine in various situations, or analyze the how new plant will perform under different conditions.

Start process optimization in your company today. Our experts will be happy to advise you on how to make the best use of iPhysics to achieve optimal results.

How simulation software is used

When monitoring running machines, simulation software can help detect and prevent problems early on. By continuously collecting real-time data, engineers can constantly simulate how a machine will perform and can predict, for instance, when a part will need to be replaced (predictive maintenance) before it malfunctions. They can also evaluate the potential impact on a system by simulating different scenarios, such as overload or a broken component.

Overall, simulation software offers an effective way to analyze and optimize complex systems without having to run expensive and time-consuming physical tests, thus helping to find the optimal solution.

Learn more about iPhysics and its benefits for your company. Test it for free and without obligation with our live demo.

Simulation software in sales and marketing

Persuade new customers right from the start with images and videos of the machine they are planning. Simulation models are particularly helpful to sales and marketing, as product performance can be assessed using realistic images and videos even before it is purchased. Every single component can be viewed from all angles with the help of 3D systems, and the customer can get a precise look at every area of the model. These early results show the desired solutions and provide all the information a potential customer needs to make their decision

Learn more – our user reports give insight into how other companies have successfully put iPhysics to use.

What are the benefits of simulation software?

Using software to visualize and model simulations offers numerous benefits including:

- Cost efficiency: Simulation software can help reduce the cost of physical testing and prototyping. Virtual testing based on this analysis can be done faster and more cost-effectively.

- Time savings: Virtual commissioning can be done in a fraction of the time needed for actual commissioning without simulation, which also accelerates the product development process. Any problems discovered can be quickly and easily avoided and taken into account in further planning. The results of the simulation and the prediction of machine behavior are available to the user at any time and can be used to select components and for further production and calculations.

- Risk mitigation: Conducting virtual tests can help identify potential risks and correct them early on, before the system is put to use in the real environment. This can reduce costs and risks associated with fixing errors and problems in later development phases. Supporting teams with better quality from the outset is also a benefit.

- Flexibility: Simulation software allows for virtual simulation of scenarios and conditions that would be difficult or even impossible to replicate in the real world. The manufacturers and suppliers of the systems are thus able to adapt the development and design of their products.

- Improved decision making: Simulation software can help companies make better decisions by allowing them to test different options and features virtually, and evaluate the impact on products before making a final decision. This early validation of results ensures that planned models are comprehensively analyzed. Thanks to 3D models, future users can be brought on board at the beginning of development. The planned products are developed using the analysis, and the optimal production and development solution can be found, taking profitability into account.

- Scalability: Simulation software can be applied to various systems and processes, making it a scalable tool and versatile solution for different industries and applications.

- Flexibilität

Eine Simulationssoftware ermöglicht es, verschiedene Szenarien und Bedingungen virtuell zu simulieren, die in der realen Welt möglicherweise schwer oder unmöglich zu replizieren wären. Die Hersteller und Anbieter der Anlagen sind so in der Lage, die Entwicklung und das Design ihrer Produkte an die Modelle anzupassen.

- Verbesserte Entscheidungsfindung

Eine Software für die Modellerstellung durch Simulation kann dazu beitragen, bessere Entscheidungen zu treffen, da verschiedene Optionen und Funktionen virtuell getestet und deren Auswirkungen auf die Produkte bewertet werden können, bevor eine finale Entscheidung auf Basis der Daten getroffen wird. Diese frühzeitige Validierung der Ergebnisse sorgt für eine umfassende Analyse der geplanten Modelle. Die späteren Anwender können dank der 3D Modelle direkt zu Beginn der Entwicklung mit an Bord geholt werden. Die geplanten Produkte werden anhand von Analysen des Tools entwickelt und schließlich die optimale Lösung für die Fertigung und Entwicklung unter Berücksichtigung der Wirtschaftlichkeit getroffen.

- Skalierbarkeit

Simulationssoftware kann auf verschiedene Systeme und Prozesse angewendet werden, was sie zu einem skalierbaren Tool und einer vielseitigen Lösung für verschiedene Branchen und Anwendungen macht.

Make the upgrade. Let us assist you in your planning. Learn more in our free webinar.

How can simulation software be used?

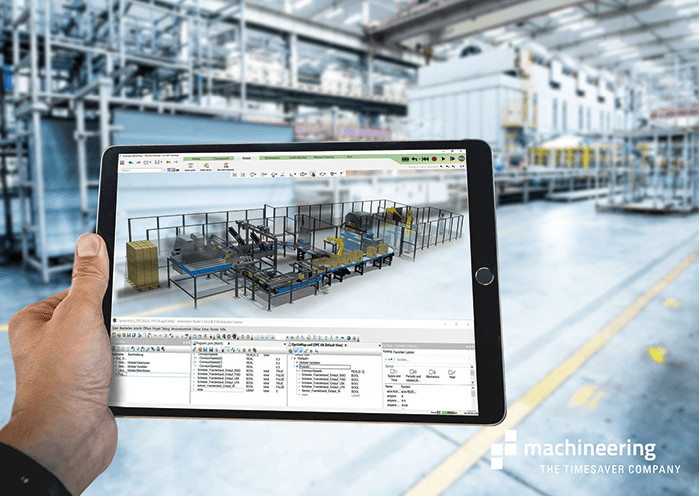

iPhysics simulation software from machineering uses two-way exchange of CAD data to provide comprehensive support for visualization, product development, modelling and production throughout the entire process. This tool is used in many different industries and applications to simulate and optimize how products, systems and processes will act.

This simulation software is especially useful in engineering to analyze the behavior of products and processes before machines are even built. It is used in many areas, including the automotive industry, mechanical engineering, aerospace and electrical engineering.

- System development: Through the use of simulation, the behavior of systems can be virtually tested and optimized long before they are actually built. This accelerates the development process and saves costs.

- Production processes: Production processes can be optimized with iPhysics by simulating the effects of changes to a process and immediately improving the efficiency and performance of the process.

- Supply chain management: This solution contributes to the optimization of supply chain performance by simulating various scenarios and analyzing their effects on the supply chain.

- Maintenance: iPhysics simulation software optimizes maintenance and repair processes by running virtual tests and identifying the best methods to resolve issues.

- Risk management: Simulation software can help identify and analyze risks in various processes by simulating different scenarios in production and analyzing their effects on the system’s functions.

Make the switch today. With our training courses, we help your employees get ready for optimized processes.

Simulation software – an indispensable tool in mechanical engineering

Simulation is a must-have tool for companies that want to model and simulate complex processes. It offers a wide range of benefits including cost savings, improved decision-making and risk mitigation. Simulation software is used in a wide variety of industries to optimize and automate processes, resulting in greater productivity.

Mechanical engineering is one industry where simulation software is especially important. Why is that?

- Avoid errors and risks: Simulation software can help reduce errors and risks in product development and the production of machines. Planning errors and malfunctions can quickly become quite expensive, especially in mechanical engineering.

- Cost efficiency: Simulation software can help reduce costs in mechanical engineering by accelerating and qualitatively improving development and production processes.

- Optimize machine performance: This software helps optimize machine performance by simulating different parameters and configurations to identify the best combination and thus find the best solution.

- Faster commissioning: Using simulation software can help reduce the commissioning time of machines by speeding up development and production. This allows companies to respond more quickly to the needs of the market and gain a competitive edge.

In summary, simulation software is essential in mechanical engineering to improve the efficiency, reliability and performance of machines and to optimize development and production.

Get the most from your company. Optimize your processes with our simulation software, iPhysics, and reap all the benefits.

Talk to us to determine your savings potential.